You ll get the first item temperature which is made because electricity goes through the tungsten electrode creating an arc for you to work with on your project.

Tig settings for sheet metal.

Those three things are heat shielding and filler metal.

This is especially useful for carbon steel.

Mig welding sheet metal.

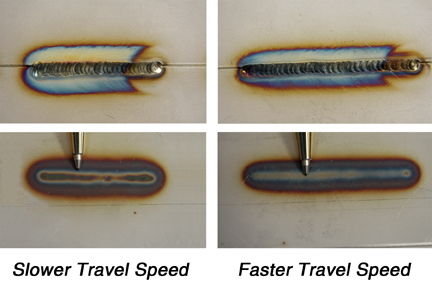

The best way to estimate the heat input needed for welding is by applying the 1 for 1 rule.

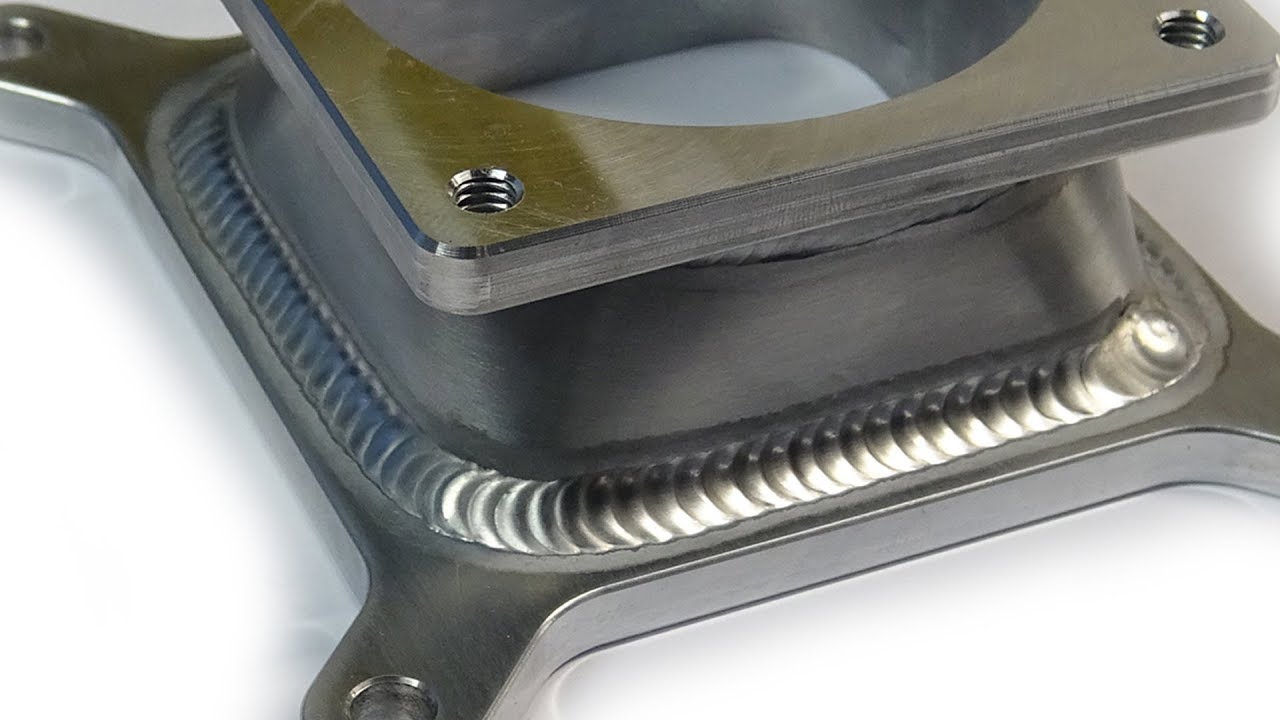

Other sheet metal applications e g stainless steel in food service typically call for a size 7 tig cup.

This means that 1 amp should be used per 1 thousandth 0 001 inch of thickness.

Sheet metal tig welding tips 1 for 1 rule.

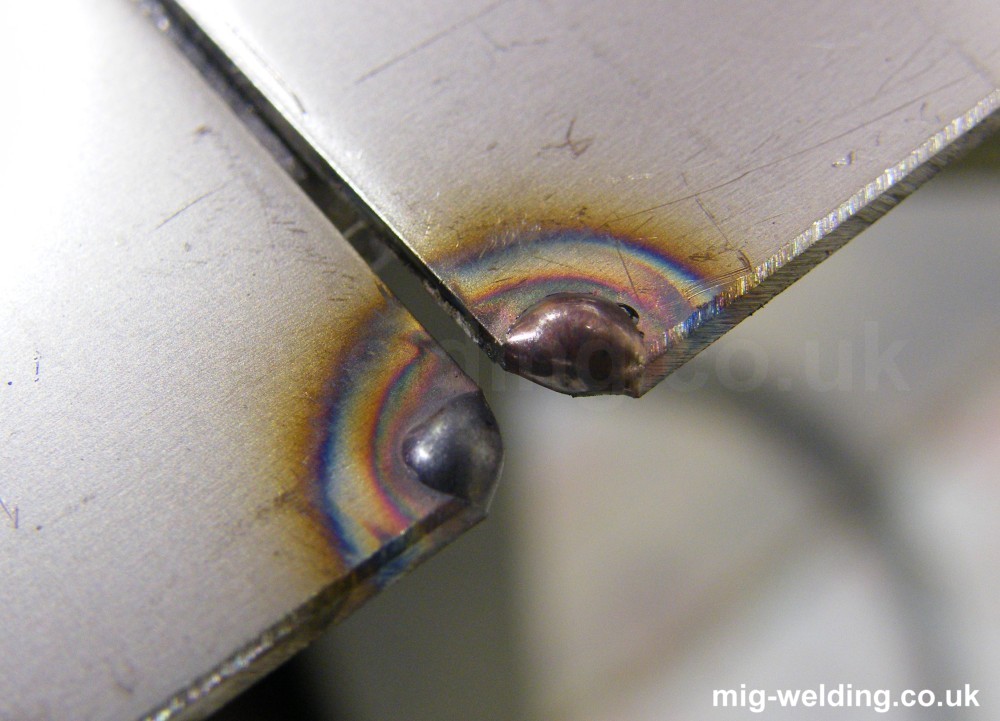

When you are tig welding with mild steel or any other metal for that matter you need to have three things.

For welding sheet metal in aerospace applications use a 15 cup 15 16 inch diameter.

How to weld auto body sheet metal with a tig welder the best two electrodes for welding auto body sheet metal is either ceriated tungsten or thoriated tungsten.

Browse suggested weld parameter settings for tig welding.

Tig welding sheet metal.

Ditch a 1 8 inch tungsten electrode for something much smaller like 1 16 inch tungsten.